“We are all born ignorant, but one must work hard to remain stupid.”

Benjamin FranklinThe decision you make when your R-22 compressor goes out boils down to the following three options:

Replace Outdoor and Indoor Units

with an R-410A System

~ $4,900

The option most commonly sold by contractors, but not necessarily the best financial decision.

Replace Outdoor Unit

with Used R-22 Outdoor Unit

~ $1,200

A good option if the coil on your outdoor unit is severely damaged and restricts air-flow.

Install New Compressor

in Current Outdoor System

~ $1,500

Typically the best financial decision overall.

I hear you saying, “What?! How in the world can replacing the compressor on my existing system be the best financial decision?” It totally depends on the facts—your facts may suggest a different choice. The key facts are:

- The ages of your current and potential replacement systems.

- The service history of your current system.

- How long you expect to own the property.

You can use these facts to estimate your total costs over time and compare your options by using the following two-step process.

Two-Steps to Making a Better Financial Decision

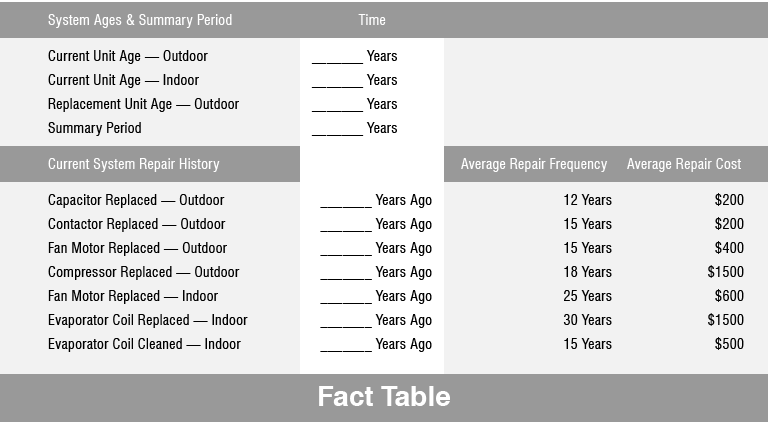

1. Complete the Fact Table below by filling in the blanks in the Time column. If you don’t know exact numbers, estimate—reasonable estimates will generate a reasonable analysis. The Repair History section of the table doesn’t list every potential repair, but it does list the repairs that are required on more than 90% of all service calls.

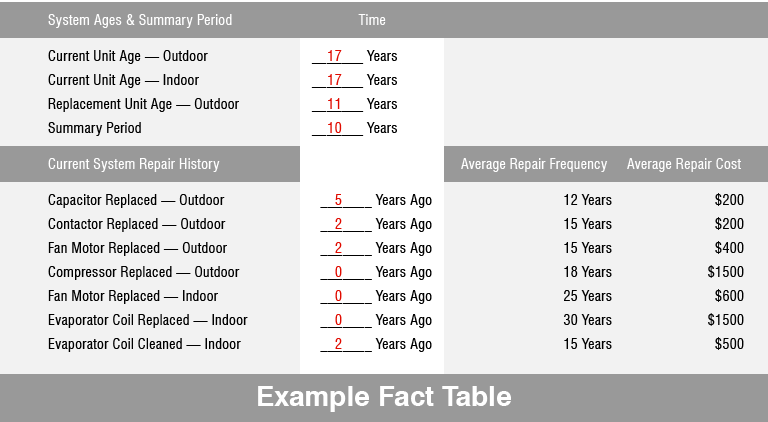

2. Compare your option costs by creating a Total Cost Table. Use the Fact Table you completed above for your numbers—assume that repairs will need to be completed based on these numbers. The best way to explain this process is through an example. Our Example Fact Table is below. We chose a ten year Summary Period—it’s roughly the amount of time most people expect to be in a home.

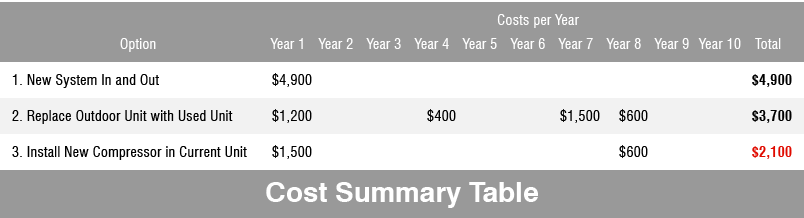

The derived Cost Summary Table is below. We didn’t include capacitor or contactor replacements because we typically install new capacitors and contactors with used condensers and new compressors; therefore, their service life is the same as a new unit. If your contractor does not install new electrical components you should add these to your numbers.

For Option 1, the ten year cost is equivalent to the first year cost because the average repair frequency of all the most common repairs is greater than ten years.

For Option 2, we replaced the outdoor fan motor in Year 4 since it would be 15 years old at that point; 15 Years (Average Repair Frequency of an outdoor fan motor) – 11 Years (Outdoor Unit Age) = 4 Years. So we added $400 to the cost in Year 4. We replaced the compressor in Year 7 and the indoor fan motor in Year 8 using the same logic.

For Option 3, we also replaced the indoor fan motor in Year 8.

Conclusion

This process is obviously simplified—it doesn’t include energy costs and/or uncommon repairs. But it is not arbitrary—it’s based on rough statistical averages. What becomes obvious when the facts are taken into account is that the cost of compressor replacement far outweighs other outdoor repairs; consequently, by getting a new compressor now, you dramatically reduce the likelihood of having to spend ~$1,500 in the near future.

We encourage you to make your own estimates. If you have special circumstances that aren’t taken into account with this process, please call and let us know. We would love to help you adapt this process for your specific needs.